Water Injected Skid Mounted Coal Bed Methane Process Screw Compressor Lgm35/0.1-0.6

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

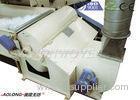

Water Injected Skid Mounted Coal Bed Methane Process Screw Compressor Lgm35/0.1-0.6

Water Injected Skid Mounted Coal Bed Methane Process Screw Compressor Lgm35/0.1-0.6

Quick Detail:

1, SERIES : LGM(water-injected)

2, MODEL: LGM35/0.1~0.6

3, STAGE : One Stage

4, POWER: 315 kw

5, CAPACITY: 35m³/min

6, SUCTION PRESSURE: 0.1MPa

7, DISCHARGE PRESSURE: 0.6 MPa

Description:

Flow of Gas-Liquid Piping System:

The flammable gas comes from the upstream flows into the compressor after purified by scrubber, and then mixed with injected coolant during the compression process, and the gas-liquid mixture will be discharged flows into the separator after compression and cooling. The separated flammable gas enters into downstream piping network as well as separated coolant re-injected into compressor internal, doing the closed circulation in this way.

Process of lubricant piping system:

Lubricating oil in lubrication oil tank pressurized into the main oil pipeline by lubricant pump, passing through the filter and the cooler entering the oil distributor before divided into several ways to the corresponding lubricating point of the compressor. Then flow back to the oil tank through oil return pipe, and the closed circulation is finished.

Applications:

The compressor set is used in the extraction and pressurization of the coal bed methane. The CBM piped to the screw compressor set after extracted through the gas well and extraction machine, and then transmitted to the downstream central processing station after pressurized by the compressor, after that purified, pressurized before liquefied and stored . And in this way a large number of available energy is transmitted to the country.

Specifications :

| Model | LGM35/0.1-0.6 |

| Capacity | 35m³/min |

| Suction Pressure | 0.1MPa(G) |

| Discharge Pressure | 0.6MPa(G) |

| Inlet Temp. | Ambient Temeperature |

| Outlet Temp. | 45 |

| Inject Medium | Water(recycling) |

| Draw Ratio |

321/1.1 |

| Driven Mode | Flexible Laminated Coupling link to Gearing Box |

| Starting Mode | Variable Frequency Starting |

| Cooling System | Air Cooling |

| Lubricating | Lubrication Pressure |

| Main Motor |

315kW( dBT4 IP55) |

| Motor Speed | 2980rpm |

| Skid Mode | Skid-Mounted |

Competitive advantages:

1. It’s a wet screw compressor, safe and reliable. It’s cooled by injected liquid to maintain a lower temperature in the compression chamber.

2. Compressor is acting continuously make the outlet pressure stable.

3.It has few wearing parts, reliable operation ,long service life and low maintenance cost.

4. High automation, the operators do not need professional training for a long time, and the unit can unattended operating.

5. Low vibration, the compressor can run steady with high speed, no foundation is realized.

6. Small size, light weight and small occupation area.

7. The effects of volume flow is almost free from the discharge pressure for the characteristics of gas forced transmission, keeping high efficiency in wide range. In circumstances of no changes of the compressor structure, it is suitable for many working conditions.

8. Baosi water-inject screw compressor is equipped with mechanical seal, to ensure the separation of gas-liquid system and lubricant oil system, so as to avoid the substances in the gas-liquid system entering the bearing lubrication oil system. Make sure the compressor running reliably.

9. Baosi screw compressor can be equipped with pre- and post processing system, making the operation more stable and make the compressed gas cleaner.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

China Induction Machine Market [China (Mainland)]

Business Type:Manufacturer

City: Foshan

Province/State: Guangdong

Country/Region: China (Mainland)